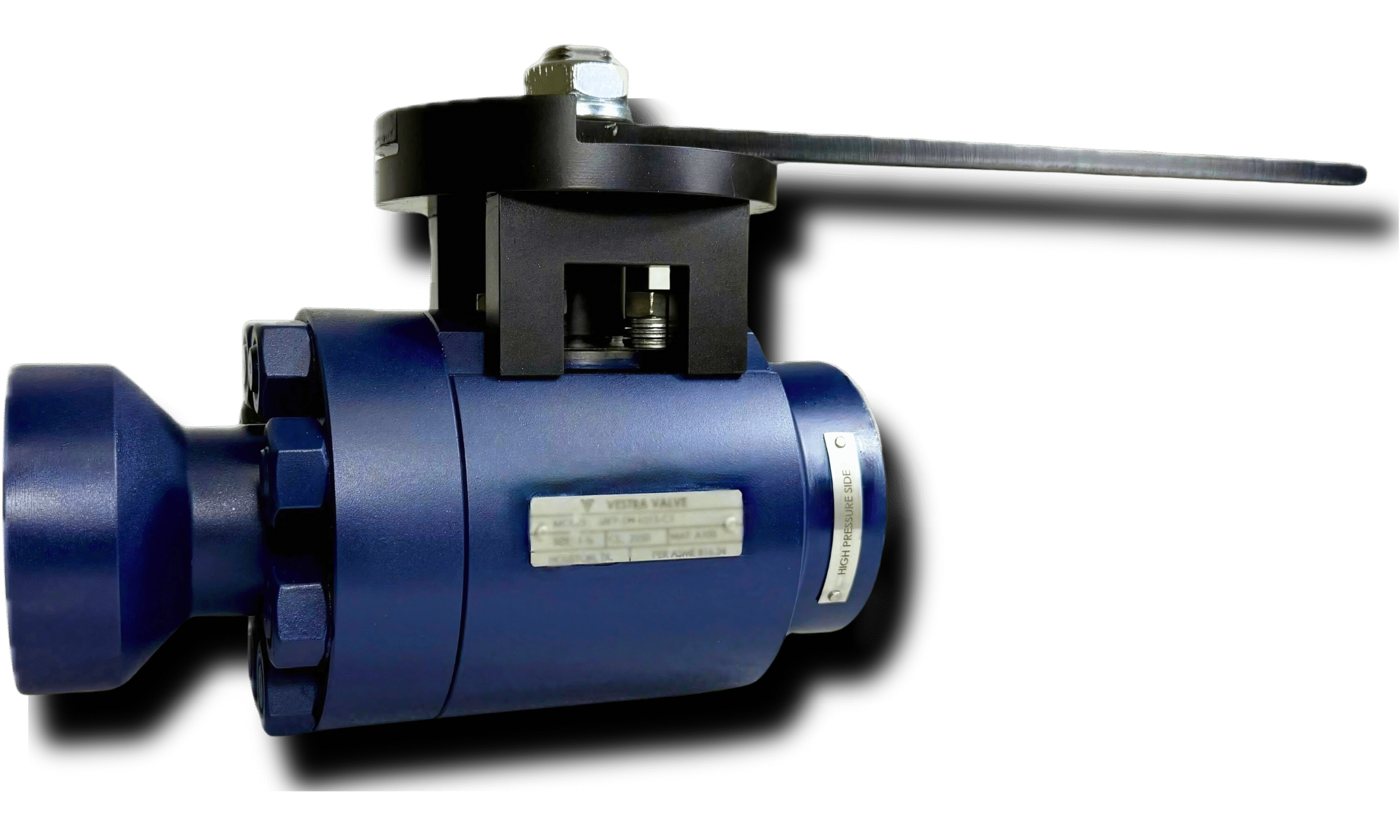

Precision Meets Performance

Metal-seated ball valve technology was born from one truth: traditional valves fail when the conditions get extreme. Industrial environments demanded more durability, more precision, and more protection where failure was not an option.

In isolation service, performance means one thing: zero leakage, anything less is unacceptable. Leakage isn’t just lost efficiency, it’s a warning sign of wear, risk, and costly downtime. Today, demand for absolute reliability has never been higher.

Vestra Valve doesn’t just meet that demand, we exceed it.

Internal Replacement Parts Kit

IN-LINE REPAIRABILITY BENEFITS

All performance critical sealing and seating components fully replaceable with brand new parts without welding and without actuator removal

INDUSTRIES

POWER

When failure isn’t an option, Vestra valves deliver. Designed for steam and power isolation, our zero-leakage, erosion-resistant designs withstand extreme cycling and heat, keeping your power plant online longer and reducing costly downtime.

INDUSTRIES

MINING & MINERALS

Mining operations face abrasive slurries, high pressures, and remote conditions that shorten valve life. Vestra valves combat erosion, leaks, and isolation failures, delivering zero-leakage shutoff and in-line repairability where downtime isn’t an option.

INDUSTRIES

OIL & GAS

From offshore rigs to midstream pipelines, oil and gas facilities demand absolute reliability. Vestra valves with chromium-carbide seating stand up to sour media, thermal shock, and high pressure, reducing failures and keeping hydrocarbons safely moving.

INDUSTRIES

PULP & PAPER

From black liquor to live steam, pulp & paper processes push valves to the limit. Vestra’s chromium-carbide seating withstands corrosion and thermal shock, helping mills reduce leaks, avoid failures, and keep production running around the clock.

Built in America, Trusted Everywhere

Behind every Vestra valve is a team of American craftsmen who know that reliability isn’t optional, it’s everything. In Houston, Texas, we handle it all: sourcing, machining, hard-facing, assembly, and final testing. Our split-body design allows for in-line repair, giving operators the ability to replace wear-critical components without pulling actuators or shutting down for welding. That’s less downtime, less cost, and more confidence in your critical systems. Vestra valves aren’t just American-made, they’re built with pride to perform where failure isn’t an option.